Blow molding machines

Blow molding machines include extrusion, injection, and stretch blow systems with servo-hybrid drives and part capacities from 0.1 to 10 liters. They are used to produce bottles, containers, automotive parts, and medical packaging from PE, PP, PET, and other thermoplastics.

Subcategories

Extrusion Blow Molding Machine TVHED-8L-2

Extrusion Blow Molding Machine PK45C-TL

Injection Stretch Blow Molding (ISBM) Machine WISBIII-88CS

Extrusion blow molding machine VNK85-1

Injection Blow Molding (IBM) Machine WIB-60

Two-station high speed extrusion blow molding machine EB70UW85

Extrusion Blow Molding Machine TVWED-1L-2

Two-station high speed extrusion blow molding machine EB30U65

Two-station high speed extrusion blow molding machine EB70UW75

Injection Blow Molding (IBM) Machine MSZ30

What is blow molding?

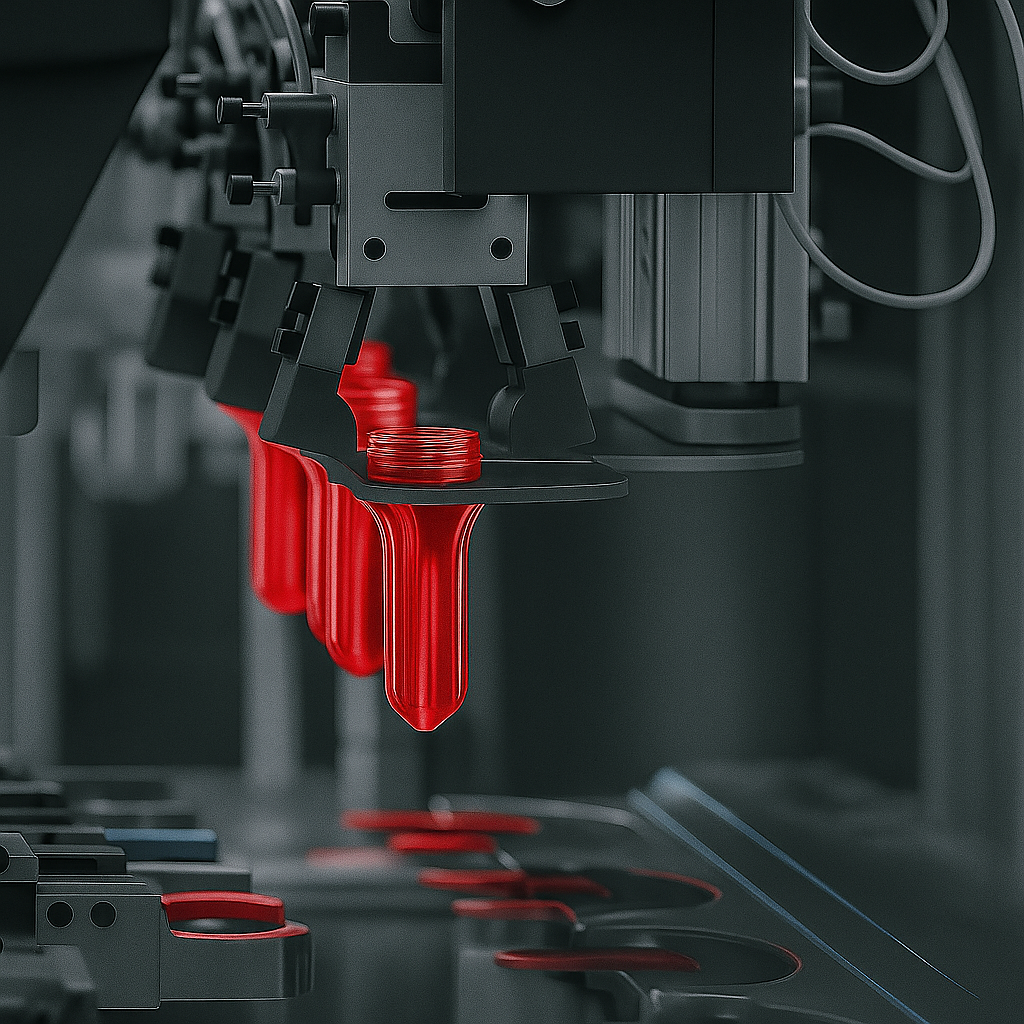

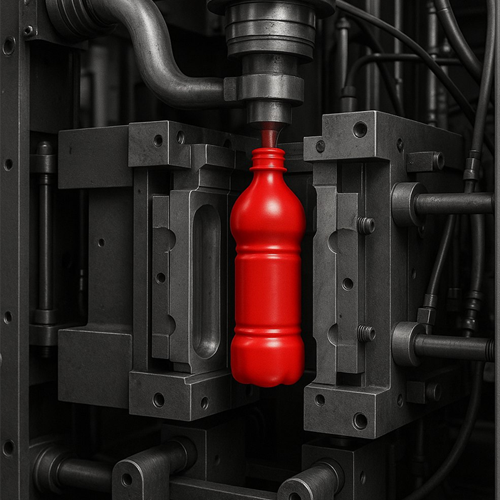

Blow molding is a molding process used in the manufacturing industry for forming of a hollow object by blowing a parison made of molten plastic in the shape of a mold cavity. With blow molding, a special machine (called "blow molding machine") blows air across heated plastic that’s placed on top of a mold cavity. The air forces the heated plastic to expand across the interior walls of the mold cavity. After the plastic cools, the finished product is finished.

Examples of parts and products that are manufactured using blow molding are water bottles, shampoo bottles and other small bottles, automotive parts, plastic chairs, cans and any other type of hollow parts.

Types of blow molding:

- Extrusion blow molding (EBM);

- Injection blow molding (IBM);

- Injection stretch blow molding (ISBM);

- Extrusion stretch blow molding (ESBM);

Blow molding advantages:

- Low cost of blow molding machinery and blow molds;

- Producing products with a small wall thickness;

- Fast production rate with little scrap generating;

High quality blow molding machines with low price from Asia by Knavi Group LLC.

Knavi Group LLC offers a large variety of reliable blow molding machines for any task by the largest manufacturers from China, Taiwan (R.O.C), Korea and Japan. A wide range of high quality machine tools with a long warranty and lowest prices. Assistance in the selection of a needed machine and equipment, installation supervision and commissioning, training, warranty and post-warranty maintenance, door-delivery to any region of the country, supply of spare parts and tools.