Electric Resistance Furnaces

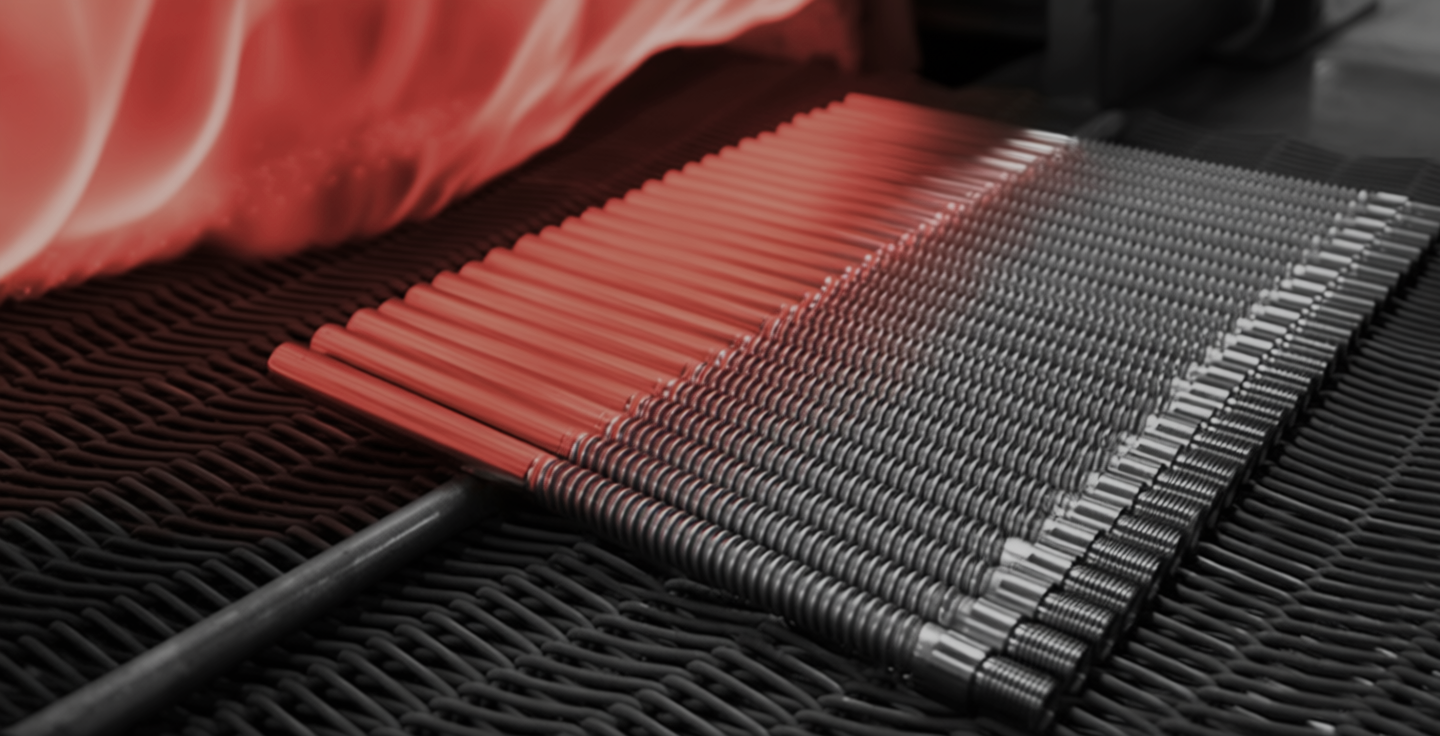

Electric resistance furnaces include conveyor models with adjustable feed speed and controlled heating/cooling zones for hardening and tempering wire springs. They are used in spring manufacturing, automotive, toolmaking, and mechanical engineering to enhance strength, elasticity, and fatigue resistance of components.

Subcategories

Continuous spring tempering furnace WNJ420

Continuous spring tempering furnace WNJ210

Continuous spring tempering furnace WNJ315

Continuous spring tempering furnace WNJ530

Continuous spring tempering furnace WNJ630

Continuous spring tempering furnace NS540

Continuous spring tempering furnace WNJ740

Electric resistance furnaces provide precise, energy-efficient heat treatment in a controlled atmosphere. Uniform temperature distribution and programmable thermal cycles ensure consistent metallurgical properties for springs, pins, fasteners, and other parts made from carbon and alloy steels.

Modern units like WNJ210, WNJ315, WNJ530, WNJ630, WNJ740, and KDE NS540 feature digital controls, inert or reducing atmospheres, and water quenching systems. With working chambers up to 4200×700×120 mm and power up to 65 kW, they handle everything from micro-springs to heavy-duty automotive components.

KNAVI GROUP supplies resistance furnaces directly from manufacturers. All equipment comes with full English documentation, up to 2 years of warranty, operator training, and optional on-site commissioning worldwide.