Heading machines

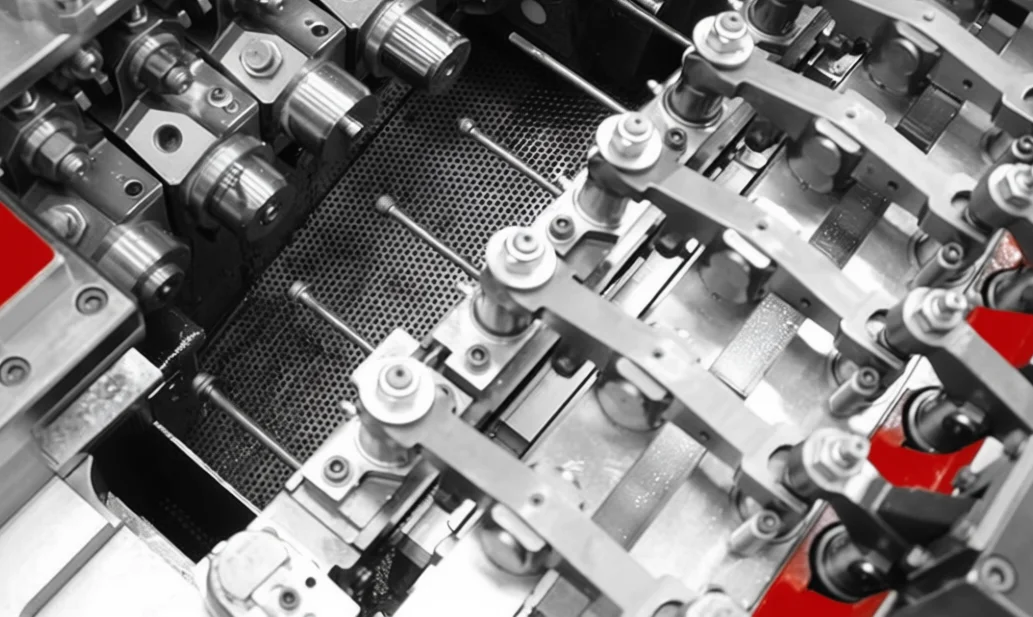

Cold forming machines include cold heading and double-blow presses for wire diameters from 3 to 14 mm, with production speeds up to 700 parts per minute. They are used for high-volume manufacturing of bolts, screws, rivets, nuts, balls, and other fasteners via cold forging without heating.

Subcategories

Threading rolling machine R4-40Z

Сold heading machine TBF-63S

Threading rolling machine R3-20Z

Threading rolling machine R5-65Z

Threading rolling machine R5-50Z

Сold heading machine TFD5-30GS

Сold heading machine TFD5-100

Сold heading machine DH-25

Сold heading machine TFD3-20

Сold heading machine TFD4-30GS

Cold forming machines produce high-strength fasteners through cold heading—a process that shapes metal at room temperature using high pressure. This preserves the grain structure of the material, resulting in superior mechanical properties compared to machined or hot-forged parts. Modern units like YUHAI TBF, TFD, TFW, and PROLU Z-G feature multi-station dies and automatic wire feeding, enabling up to 5 forming operations in a single stroke: cutoff, head forming, shaping, and sizing.

These machines are essential in automotive, construction, energy, and appliance manufacturing, where consistency, speed, and material efficiency are critical. Double-blow presses (e.g., TFD6-150) allow complex geometries through sequential deformation—ideal for specialty fasteners and high-performance components.

KNAVI GROUP supplies cold forming equipment directly from top Chinese manufacturers. All machines include full English documentation, pre-commissioning checks, and up to 2 years of warranty. Custom tooling and process development support are available for both standard (DIN, ISO) and bespoke fastener designs.

Direct factory supply ensures fast delivery worldwide. Operator training and on-site commissioning are included.