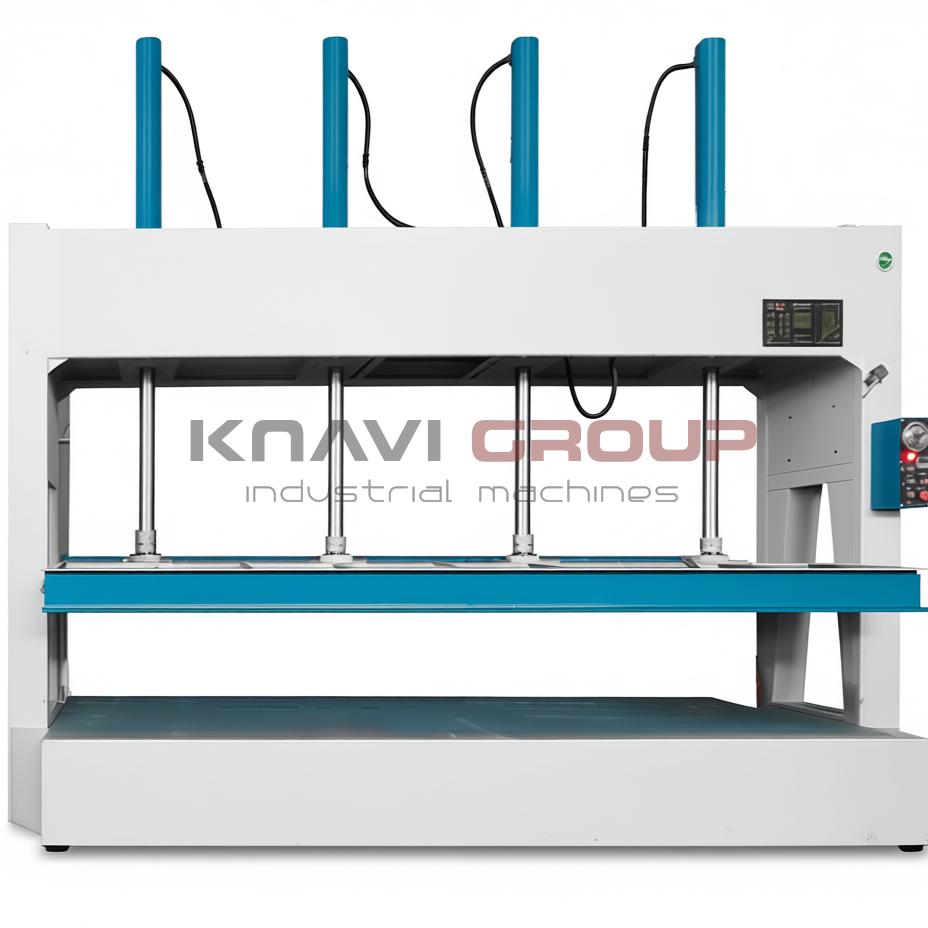

Hydraulic cold press machine MH3284x60T

Price & Terms

Specifications

Working area

Hydraulic system

Engines and power supply

Overall dimensions and weight

Description

Woodworking hydraulic cold press machine MH3284 is suitable for pressing various type of laminations on composite wood, cork board, fibre board, Honey comb board, mainly used for the plywood veneer and multilayer suppression wood door veneer. This press machine works and presses under the action of electric power. It uses position limit switch which is a guide attachment for lifting work, and large power and no-spark gauge with electric contact what increases the reliability and stability of this machine.

1. Durability and Stability

The machine body is manufactured from high-quality steel, ensuring high load resistance, minimizing deformation, and extending the equipment's service life..

2. Reliable Electrical System

All electrical components are made from high-quality materials, and the wiring layout is rational, which enhances operational reliability and reduces the risk of technical failures.

3. High-Efficiency Hydraulic System

The oil tank features a sealed one-piece structure that prevents leaks even during prolonged operation and maintains stable system pressure for precise control of the pressing process.

4. Versatility

The machine is suitable for processing a wide range of materials: composite doors, furniture panels, plywood, drywall, insulation panels, aluminum honeycomb panels, etc.

The ability to adjust pressure and press stroke according to specific tasks increases the machine's operational flexibility in various production environments.