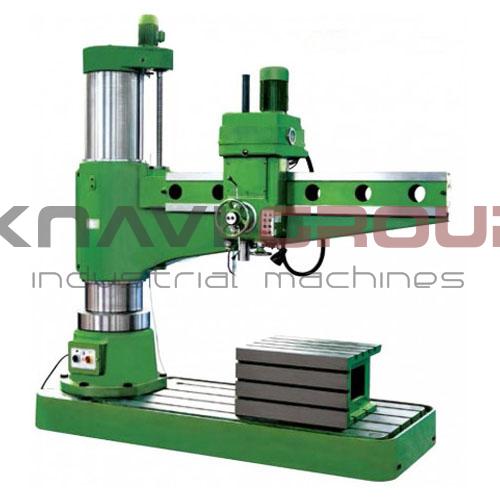

Radial Drilling machine Z3080x25/1

Price & Terms

Specifications

Capability

Headstock

Working area

Engines and power supply

Overall dimensions and weight

Overall dimensions and weight

Equipment

Description

1.Product introduction:

● Hydraulic pre-selection speed change mechanism can save auxiliary time.

●The main shaft forward and reverse rotation, parking (braking), speed change, neutral and other actions are controlled by a handle, which is easy to operate.

●The spindle box, rocker arm and inner and outer columns are clamped reliably by the diamond block clamping mechanism driven by hydraulic pressure.

●The rocker guide rail, the circular surface of the outer column, the main shaft, the main shaft sleeve and the inner and outer column rotary raceway are quenched, which can maintain the stability of the machine tool accuracy for a long time and prolong the service life.

● Complete safety protection devices and outer column protection are available.

●In terms of structural design and manufacturing process, a series of effective measures have been taken to greatly extend the accuracy durability of the machine tool and the service life of the whole machine.