Plastic processing machinery

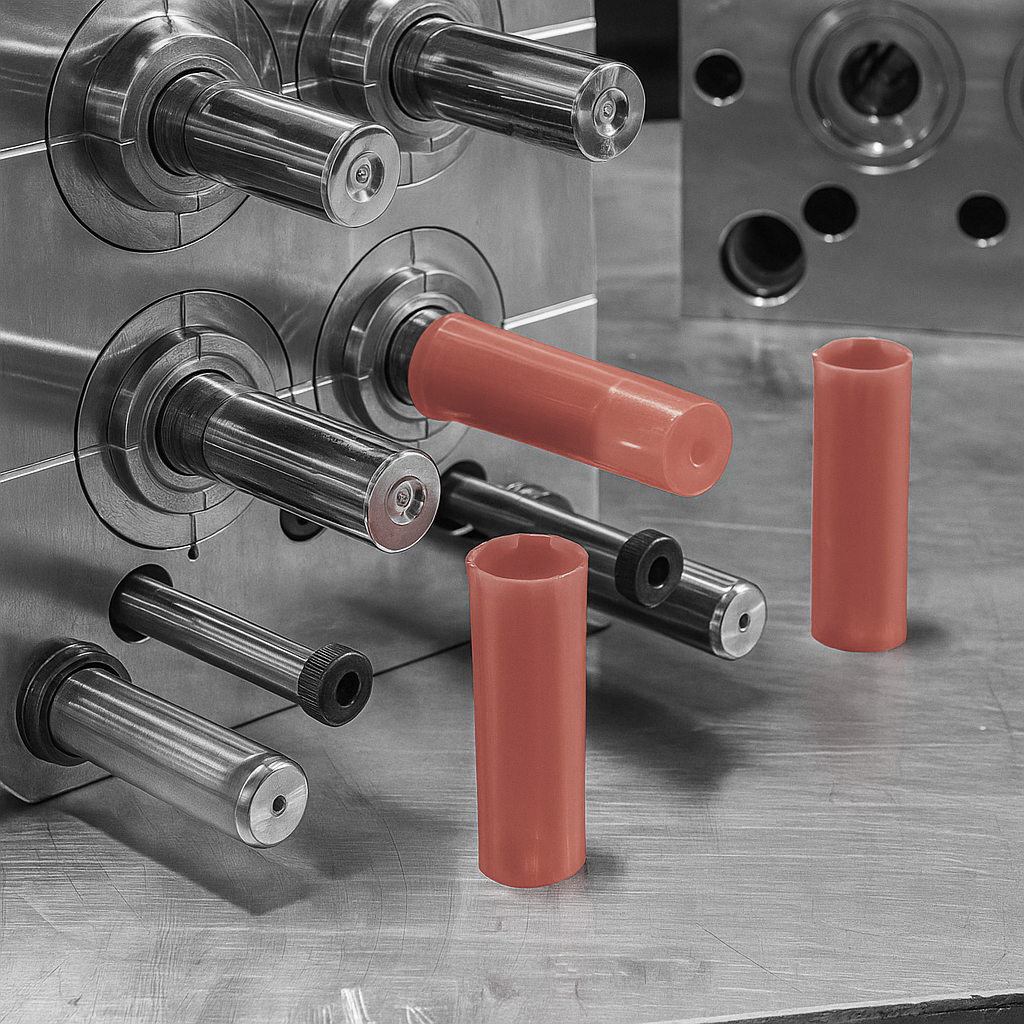

Plastic processing equipment includes hydraulic, hybrid, and all-electric injection molding machines, injection and extrusion blow molding systems, and extruders for thermoplastic processing. It is used in packaging, medical, automotive, consumer goods, and electronics industries to produce parts via injection molding, blow molding, and extrusion.

Subcategories

Servomotor Injection Molding Machine 78SJ II

Injection Stretch Blow Molding (ISBM) Machine WISBIII-75AS

Vertical injection molding machine JY-200ST

Extrusion blow molding machine VNK85-1

Vertical injection molding machine JY-450ST-D

Single-component Injection molding machine V4-S-35T

Two-station high speed extrusion blow molding machine EB70U85

Single-component Injection molding machine V4-S-15N

Servomotor Injection Molding Machine HD100L

Single-component Injection molding machine V4-SD-15N

Modern plastic processing systems enable the production of components ranging from disposable containers and medical syringes to appliance housings and automotive interior parts. Injection molding machines with clamping forces from 25 to 1600 tons deliver high repeatability, cycle stability, and energy efficiency through servo-hydraulic or all-electric drives and intelligent control systems.

Injection blow molding machines produce seamless, hermetic containers—ideal for pharmaceuticals, cosmetics, and food packaging. Extrusion blow molding systems handle large-volume items like drums, fuel tanks, and IBC containers. Extruders are used for profiles, sheets, films, and pipes.

KNAVI GROUP supplies equipment from top Asian manufacturers including HAIDA, JIE YANG, PowerJet, MULTIPLAS, and Jingye Machinery. All machines undergo pre-shipment inspection, come with full English documentation, and include up to 2 years of warranty. Turnkey solutions—from line design to commissioning and operator training—are available.

Direct factory supply ensures competitive pricing. On-site commissioning and training are provided worldwide.