Stone-sawing machines

Stone cutting machines include single-blade, multi-blade, bridge, cantilever, and wire saw models with manual, PLC, or CNC control. They are used for block and slab cutting of granite, marble, porcelain, and quartzite in stoneworking facilities of all scales.

Single column single-blade block cutting machine QZQ-1800

Bridge-type multiblade stone block cutting machine HQQ-2500

Stone block squaring cutting machine LMX-3850

Natural stone (granite, marble, onyx, basalt, travertine, etc.) is used in all sectors of life: architecture and construction, furniture (countertops, sinks, benches) and interiors, road construction, the manufacture of monuments, sculptures, tombstones, etc. For the manufacture of any stone product, it is necessary to saw a stone block mined in a quarry. This operation is carried out by stone-sawing machines.

Stone cutting machines have a rigid frame with mounted on it drivers for rotating the cutting tools and for moving the machine. The cutting tools of stonecutting machines are circular saws and chain or wire (rope) cutters equipped with hard-alloy teeth.

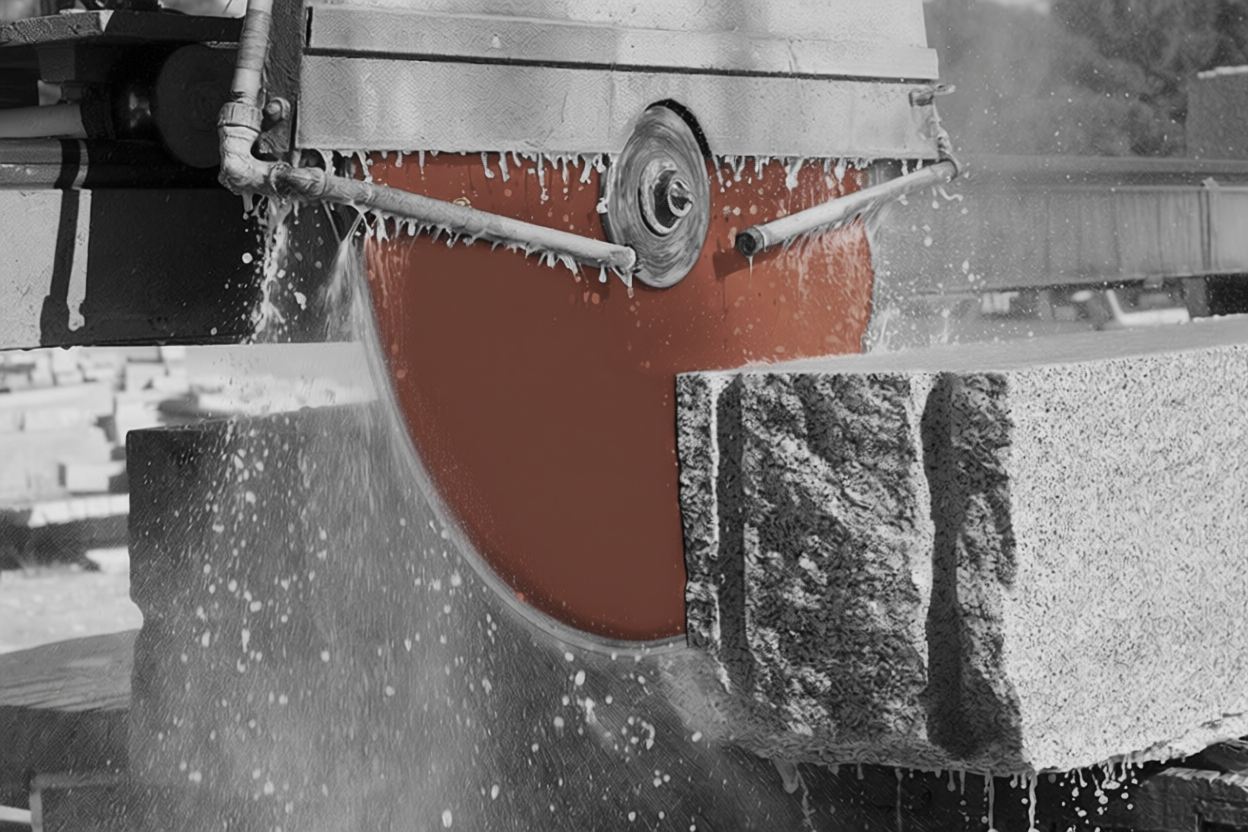

- Disc saw cutting

The cutting tool is a steel alloy disc with diamond segments welded to the periphery. Depending on the thickness to be cut the size of the disc can vary, ranging between 300 mm and 4 metres in diameter. Large disc machines are fitted with discs of 4 metres in diameter with segments that are 14 mm thick. Such machines, when fitted with powerful motors of up to 110 kW, can open large blocks measuring 1.7 metres. - Wire cutting

The cutting tool is a steel wire, usually from four to fifteen millimetres thick, on to which diamond beads, as they are called, are attached. These beads have the same structure as the diamond segments: sintered polycrystalline diamonds in a metal matrix. There must be separation between the diamond beads to allow for the removal of cut away material, and 30 – 40 beads are usually fitted per metre. The element separating the beads may differ depending on the type of wire, which may be springs or injected polymer, but normally vulcanised rubber or plastic. - Band saw cutting

The saw consists of a flexible strip and merlons with welded diamond segments on its ends. As the strip is very narrow, small 3 mm thick segments can be welded, by which a major reduction can be achieved in cutting thickness.

Reliable and durability stone cutting machines from Asia by Knavi Group LLC.

Knavi Group LLC offers a large variety of reliable stone-sawing machines for any task by the largest manufacturers from China, Taiwan (R.O.C), Korea and Japan. A wide range of high quality machine tools with a long warranty and lowest prices. Assistance in the selection of a needed machine and equipment, installation supervision and commissioning, training, warranty and post-warranty maintenance, door-delivery to any region of the country, supply of spare parts and tools.