Home

/

Machine tools and equipment

/

Bending and forming machinery

/

Wire forming machinery

/

Spring coiling machines

/

7 axis spring coiling machine JTC 720

JOINT

7 axis spring coiling machine JTC 720

Series

JTC7

Quantity of controlled axis

7pcs

Wire diameter

0.5mm — 2mm

Wire feed value

0.01mm — 10000mm

Wire feeding speed

100m/min

Price & Terms

Price on Request

Specifications

Basic feauturies

Quantity of controlled axis

7pcs

Type of spring

Compression / Torsion

CNC

Spring coiling machine computer

Windows based

CNC language

Chinese / English

Interactive programming

No

Yes

Processing parameters

Wire diameter

0.5mm — 2mm

Wire feed value

0.01mm — 10000mm

Wire feeding speed

100m/min

Direction of coiling

Right + Left

Wire feeding wheel pressing mode

Mechanical

Controlled axes

Outer diameter control mode

Two curves (CAM modes)

OD control axis

1.2kW

Wire feed axis

1pcs x 2.7kW

Pitch axis

1pcs x 0.75kW

Arbor moving axis

0.4kW / 1.2kW

Cutting axis

0.75kW / 0.75kW

Engines and power supply

Voltage

380V / 50Hz / Three phase / AC

Total motor power

7.75kW

Overall dimensions and weight

Weight

800kg

Overall length

1350mm

Overall width

800mm

Overall height

1800mm

Peripherals

Wire feeders

✅

JTC-200

Type

: Full-automatic

,

Diameter of feeding tray

: 850mm

,

Loading weight

: 200kg

,

Motor power

: 0.75kW

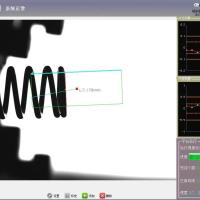

Spring length detector

CXYX-1

Spring detector

: Monochrome Industrial Camera

,

Measurement speed

: 200pcs/min

,

Spring lenght sorting device

: Presence

Equipment

✅

Diamond needle files

(Default)

Quantity:

1 set

✅

Grease gun

(Default)

Quantity:

1 pcs

✅

Left-direction coiling knife rest

(Default)

✅

Manual lubrication of guides

(Default)

✅

Oil gun

(Default)

Quantity:

1 pcs

✅

Pneumocylinder

(Default)

Quantity:

1 pcs

✅

Probe

(Default)

Quantity:

2 pcs

✅

Right-direction coiling knife rest

(Default)

✅

Safety guard

(Default)

✅

Tooling for coiling

(Default)

Quantity:

1 set

0.5mm / 0.6mm / 0.7mm / 0.8mm / 1.0 mm / 1.2 mm / 1.4mm / 1.6mm / 1.8mm / 2.0mm

✅

Tools box

(Default)

Quantity:

1 pcs

Torsion spring making unit

✅

Work area lighting lamp

(Default)

Quantity:

1 pcs

Description

7-Axis Spring Coiling Machine – Model JTC 720

The JTC 720 is a 7-axis CNC spring coiling machine designed for high-speed production of springs made from medium wire with diameters ranging from 0.5 mm to 2.0 mm. The 7 CNC-controlled axes significantly simplify setup and changeover, especially when compared to traditional 2- or 3-axis machines.

Types of Springs That Can Be Produced:

- Compression springs: conical, cylindrical, barrel-shaped

- Gland (stuffing box) springs

- Simple torsion springs

- Extension springs with hooks formed from full coils (<60°)

Standard Equipment Includes:

- Wire feeding unit with 200 kg load capacity

- Electromagnetic length sensor with ±0.005 mm accuracy and automatic sorting function

Optional Equipment:

- Industrial camera for precision and geometry inspection with automatic sorting

- Tooling set for producing basic torsion springs

Commercial Offer Request

Product Information

Brand

JOINT

Model

JTC 720

Series

JTC7

Price

Price on Request

Selected Configuration

Interactive programming:

No

Selected Peripherals

Wire feeders:

JOINT JTC-200

Equipment Package

Diamond needle files

Grease gun

Left-direction coiling knife rest

Manual lubrication of guides

Oil gun

Pneumocylinder

Probe

Right-direction coiling knife rest

Safety guard

Tooling for coiling

Tools box

Work area lighting lamp

Please fill out the form above