Face milling machine X1220

Price & Terms

Specifications

Working table

Horizontal headstock

Engines and power supply

Overall dimensions and weight

Peripherals

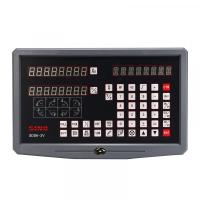

Digital Readout Unit (DRO)

Equipment

Description

Key Advantages of the X1220 Face Milling Machine

Versatile Working Area for Large-Sized Workpieces

Table size: 1200 × 2000 mm, enabling machining of long components and structures without additional re-fixturing

High table load capacity supports processing of heavy metal constructions

High Productivity in Face Milling Operations

Feed motor power: 3 kW, ensuring stable performance when machining hard materials

Stepless feed speed adjustment for optimized processing parameters based on material type and workpiece geometry

Capability to machine multiple surfaces simultaneously in a single pass

Robust Construction for Industrial Applications

Monolithic bed cast from high-strength cast iron with optimized geometry to minimize vibrations

Overall dimensions ensure machine stability even when processing large workpieces

Industrial-grade assembly using precision components for long-term reliability in serial production environments

Versatility in Metalworking Applications

Designed for face milling of welded and hot-rolled I-beams

Efficient machining of box-section beams and other profiled structural elements

Suitable for weld edge preparation, chamfering, and groove cutting on metal structures

Ease of Operation and Setup

Mechanical or electromechanical control system with intuitive adjustment controls

Option for manual or automatic feed to provide flexibility in operating mode selection

Minimal setup time required when switching between different workpiece types

Products in This Series

Compare Series Products

Face milling machine X1220