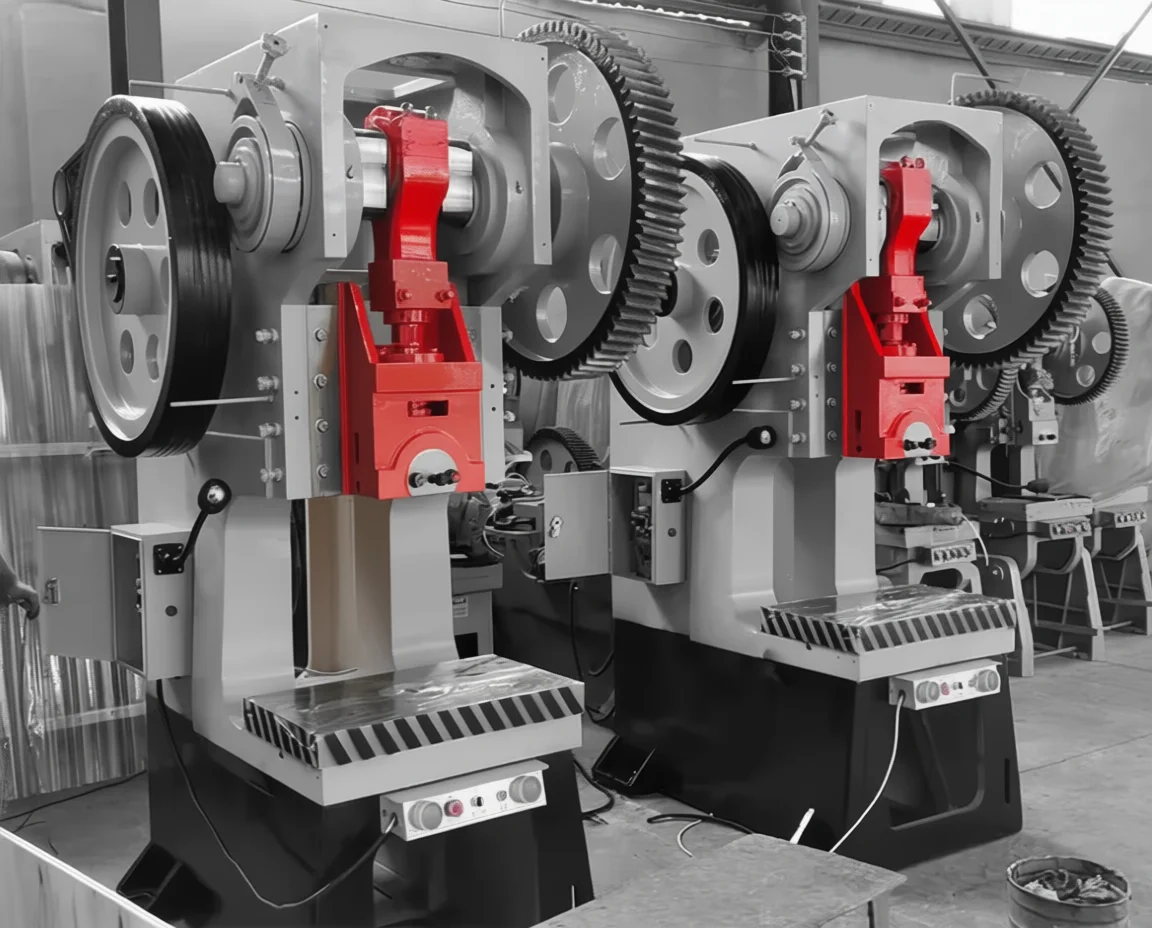

Punching and forging presses

Punching and stamping presses are available in models from 0.5 to 63 tons, featuring manual or electromechanical drives and push-button controls. They are used for perforating, blanking, bending, and forming sheet metal in mechanical engineering, construction, utilities, and maintenance workshops.

Subcategories

Punching press JC23-6.3

Punching press JE21-40D

Punching press JB04-1.0T

Punching press JB04-2T

Punching press JC23-63A

Punching press JB04-3T

Punching press JB04-6.3T

Punching press JB04-6.3T

Punching press JB04-1.5T

Punching press JB04-0.5T

Punching and stamping presses enable efficient cold-forming of sheet metal without thermal distortion. Their robust mechanical design ensures high repeatability and durability—even under continuous industrial use. Compact models (e.g., Shuangwei JB04, 0.5–6.3 tons) suit small workshops, while heavy-duty units like YangLi JC23 and JE21 (up to 63 tons) support high-volume production in manufacturing plants.

Modern presses include safety features such as two-hand control, protective guards, and stroke limiters to comply with international safety standards. Quick-change tooling allows rapid switching between operations—hole punching, notch cutting, flanging, or custom stamping—on materials from thin steel to 12 mm thick plates.

KNAVI GROUP supplies presses directly from top Chinese manufacturers. All units undergo pre-shipment inspection, come with full English documentation, and include up to 2 years of warranty.

Direct factory supply ensures fast delivery worldwide. Operator training and on-site commissioning are available upon request.