Stone processing machinery

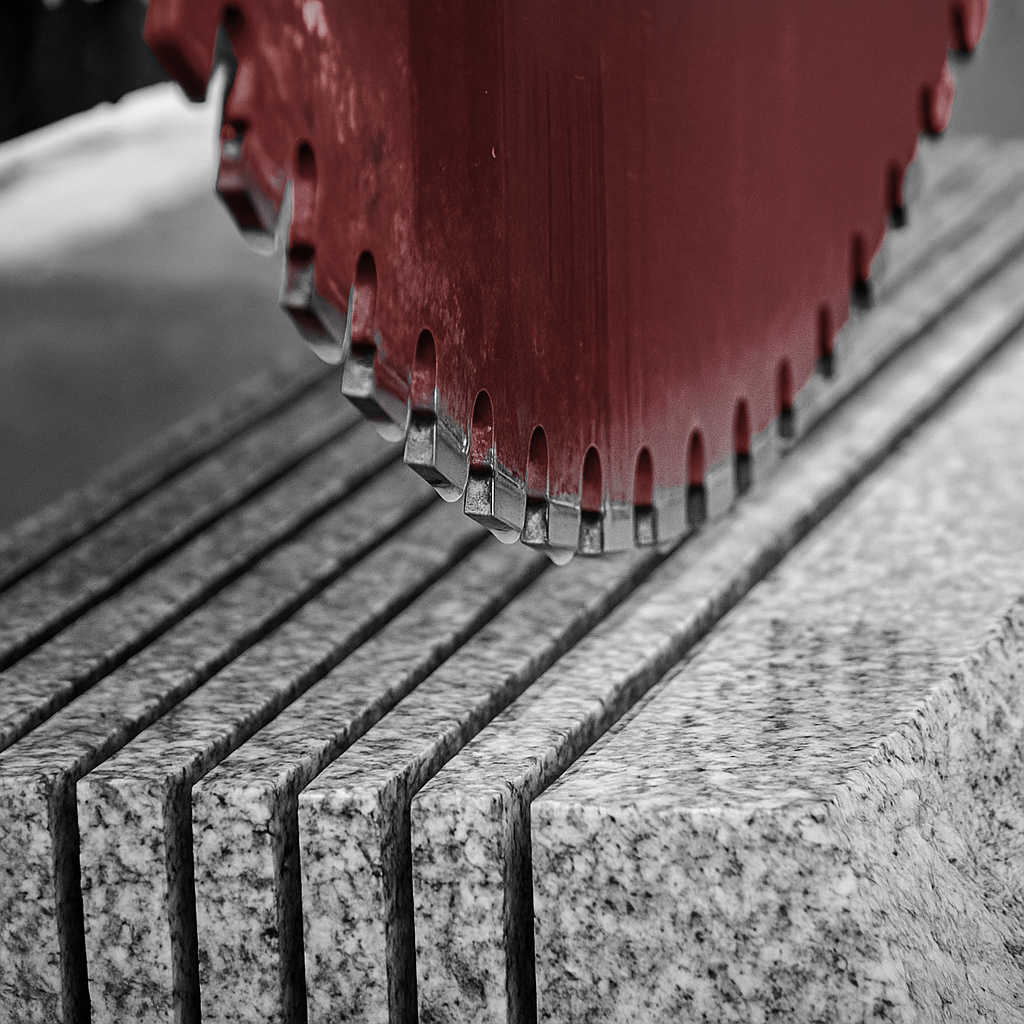

Stone processing machines include single-blade, multi-blade, bridge, and cantilever models with PLC or CNC control for cutting, grinding, polishing, and edging natural and engineered stone. They are used in the production of slabs, stairs, countertops, memorials, and architectural stone elements.

Tile Splitting Machine BFQ-800

Single column multi-blade block cutting machine HSAM-2200

Single column stone block cutting machine HSAM-2500

Bridge-type stone block cutting machine HQQ-1200

Table type manual block cutter HTCM-1000С

Edge Polishing Machine MBJ99

Gantry-type stone cutting machine LMQ-3000

Stone block squaring cutting machine LMX-4850

Disc-saw stone cutting machine QZQ-900

Gantry-type Stone cutting machine LMQ-2200

Modern stone processing equipment delivers high precision and efficiency when working with hard materials like granite, marble, quartzite, porcelain slabs, and composites. Single-blade machines (e.g., SYQ-600) excel at profiling and edge finishing, multi-blade saws enable high-volume batch cutting, while CNC bridge saws handle complex 3D contours and bevels with minimal manual intervention.

All machines feature diamond blades, water-cooling systems, automatic feed, and precise angle adjustment (0°–90°), ensuring clean, chip-free cuts even on brittle materials. Brands like KDE, Hizar, Montalbano, and Stone Group offer scalable solutions—from compact units for small workshops to fully automated lines for industrial stoneworking facilities.

KNAVI GROUP supplies stone machinery directly from manufacturers. Every unit comes with full English documentation, up to 2 years of warranty, operator training, and optional on-site commissioning worldwide.