9 axis spring coiling machine JTC 950

Main Configuration

Price & Terms

Specifications

Basic feauturies

CNC

Processing parameters

Controlled axes

Engines and power supply

Overall dimensions and weight

Peripherals

Spring length detector

Wire feeders

Equipment

Description

JTC950 9-Axis Spring Coiling Machine

The JTC950 is a 9-axis spring coiling machine designed for high-speed production of springs made from medium-diameter wire ranging from 1.2 mm to 5.0 mm. The 9 CNC-controlled axes greatly simplify machine setup and changeover. Adjustment and control of the coiling points responsible for the spring's outer diameter are achieved via individual motors rather than a cam-and-crank mechanism. Additional features include a horizontally retractable winding unit, CNC-controlled extension of the central mandrel, and vertical movement of the mandrel.

Types of Springs That Can Be Produced:

- Compression springs: conical, cylindrical, barrel-shaped

- Gland (stuffing box) springs

- Simple torsion springs

- Extension springs with hooks formed from full coils (<60°)

Standard Equipment Includes:

- Wire feeding unit with 700 kg load capacity

Optional Equipment:

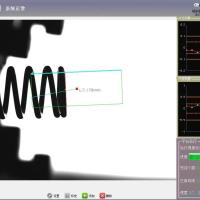

- Industrial camera for precision and geometry inspection with automatic sorting

- Tooling set for producing basic torsion springs

Products in This Series

Compare Series Products

9 axis spring coiling machine JTC 920

9 axis spring coiling machine JTC 926

9 axis spring coiling machine JTC 940

9 axis spring coiling machine JTC 950

9 axis spring coiling machine JTC 960