Grinding machines

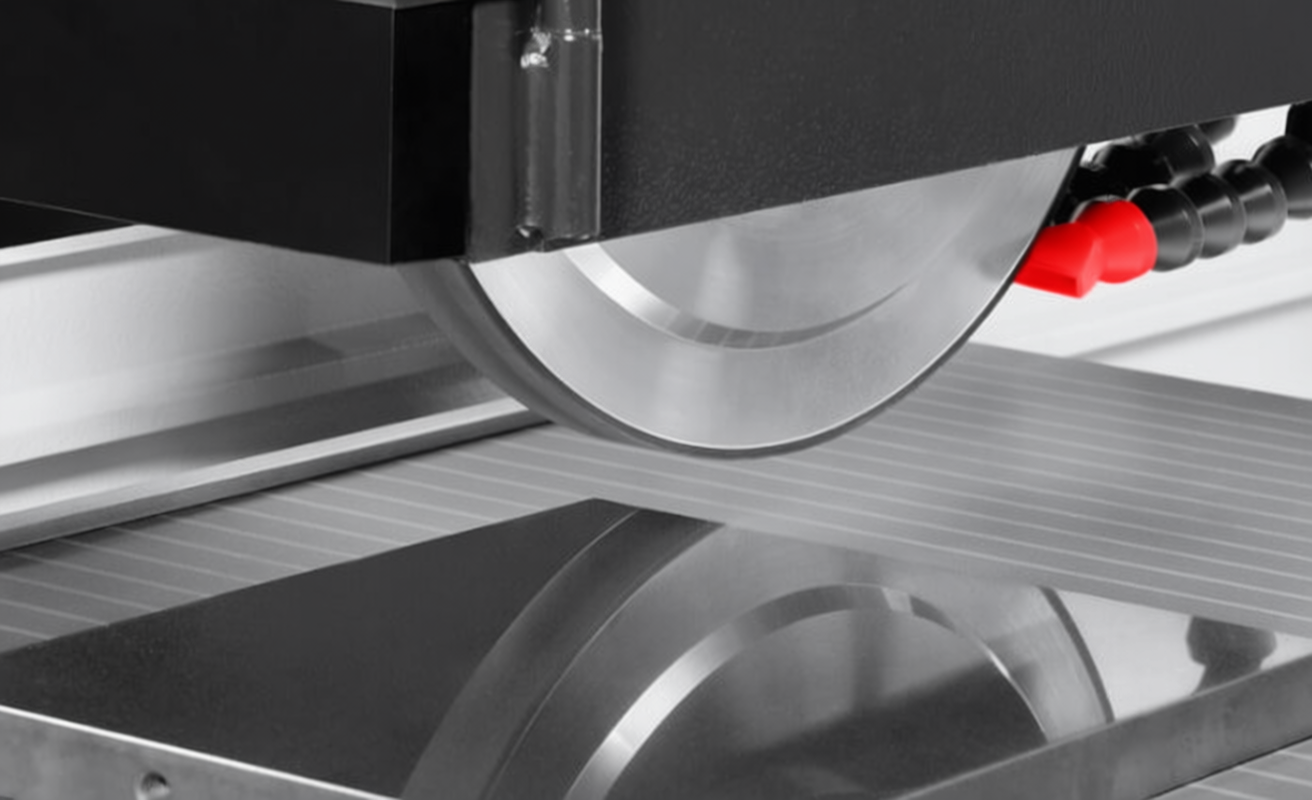

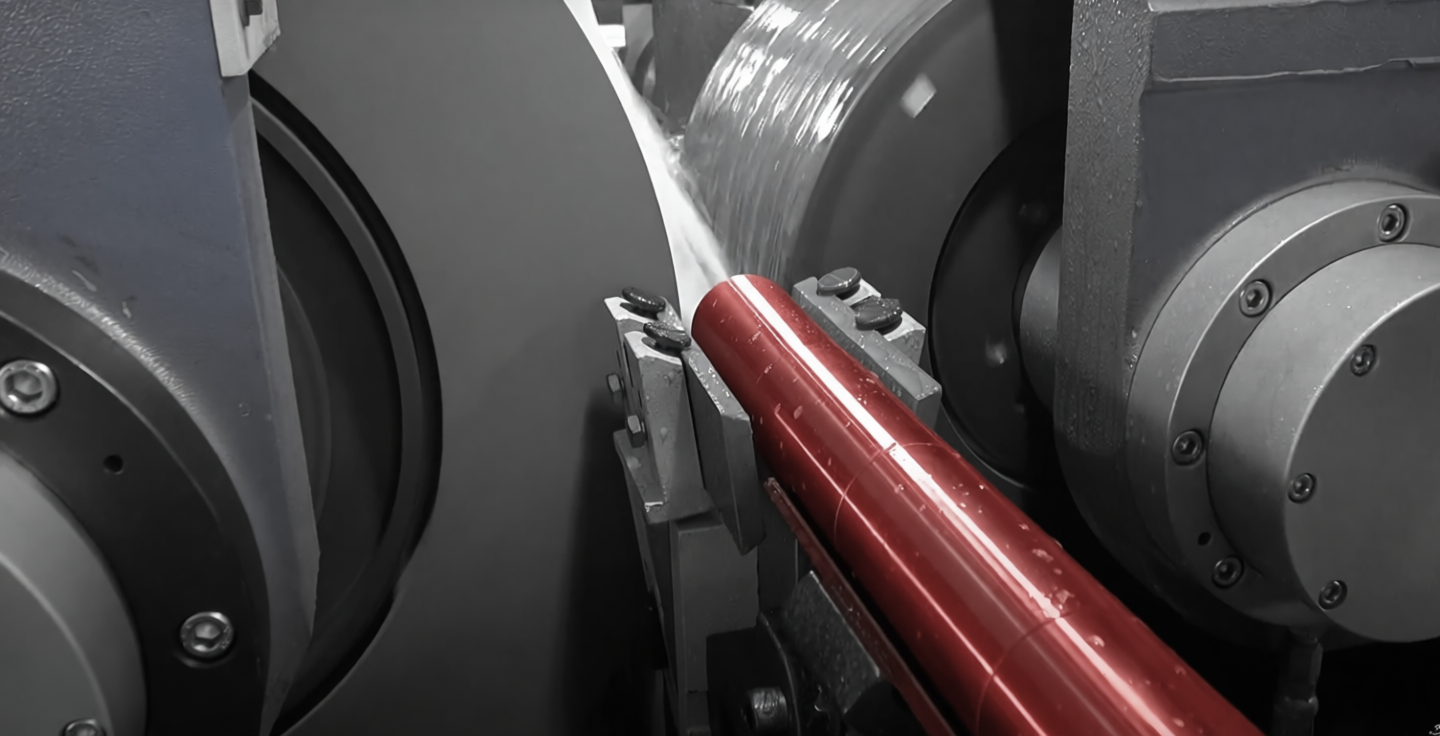

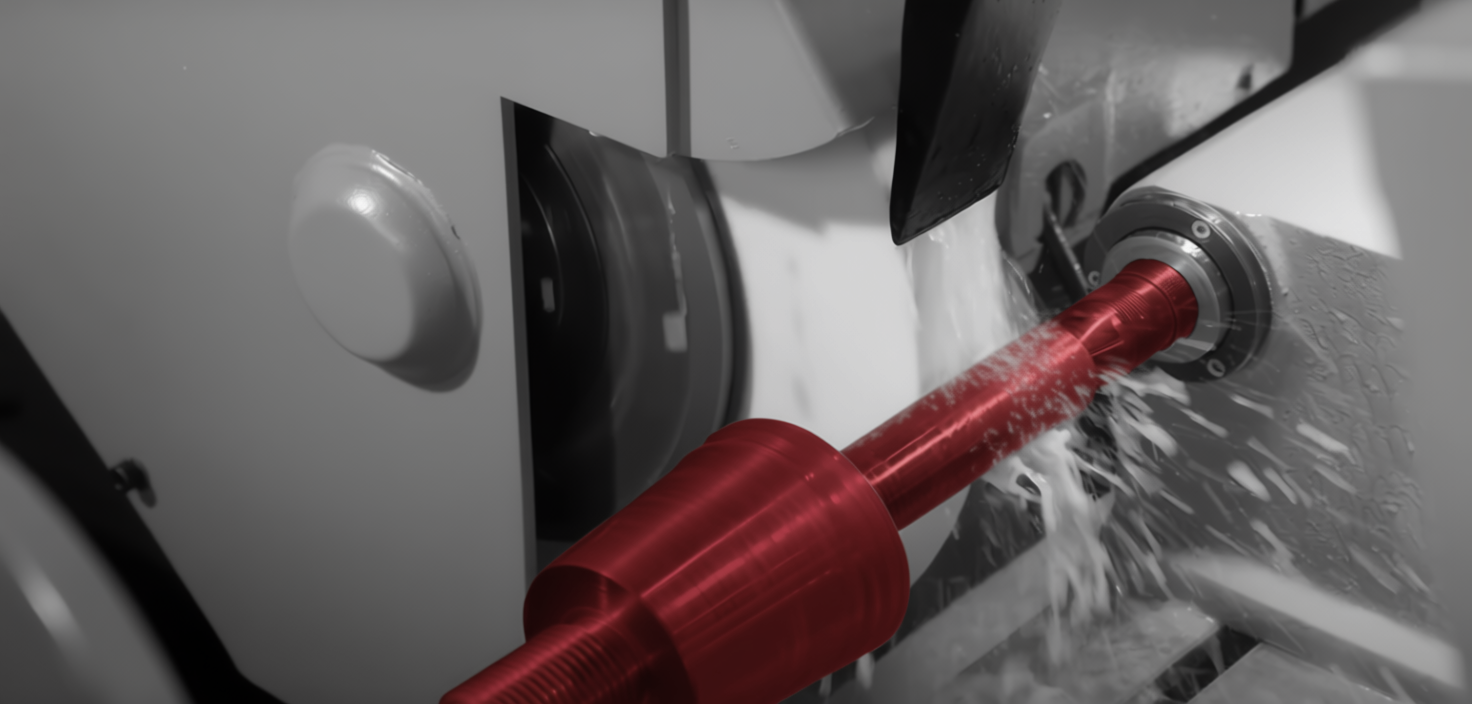

Grinding machines include surface, cylindrical, internal, and centerless models for high-precision finishing of metal components. They are used in mechanical engineering, toolmaking, energy, and aerospace industries to process shafts, rings, plates, spindles, and precision parts.

Surface Grinding Machine M7150

Surface Grinding Machine KGS510AHR

Surface Grinding Machine KGS515AHR

Surface Grinding Machine KGS620AHR

Surface Grinding Machine KGS510AHD

Surface Grinding Machine KGS515AHD

Surface Grinding Machine KGS615AHR

Surface Grinding Machine KGS615AHD

Surface Grinding Machine M7180

Grinding machines deliver micron-level surface refinement after rough machining, ensuring geometric accuracy and minimal runout. Surface grinders are ideal for flat reference surfaces, cylindrical grinders for shafts and spindles, internal grinders for bores and bushings, and centerless grinders for high-volume production of pins, rollers, and rods without centering.

Modern units from SMTCL, DMTG, WEIDA, KDE, and Caiman feature CNC control, wheel wear compensation, digital readouts, and automation interfaces. Rigid cast frames and precision guideways enable surface finishes as fine as Ra 0.2 µm and positioning accuracy within ±0.002 mm.

KNAVI GROUP supplies grinding machines directly from manufacturers. All equipment comes with full English documentation, up to 2 years of warranty, operator training, and optional on-site commissioning worldwide.