Metalworking machine tools

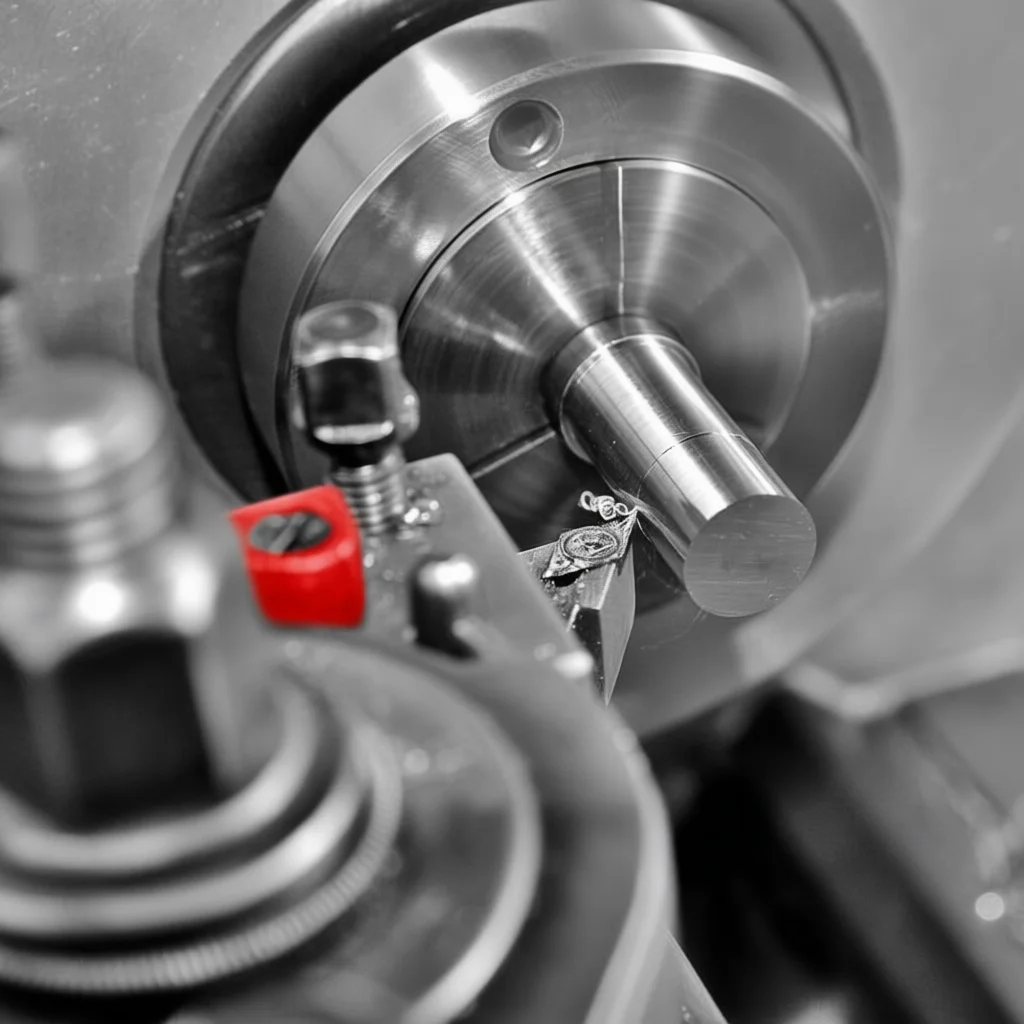

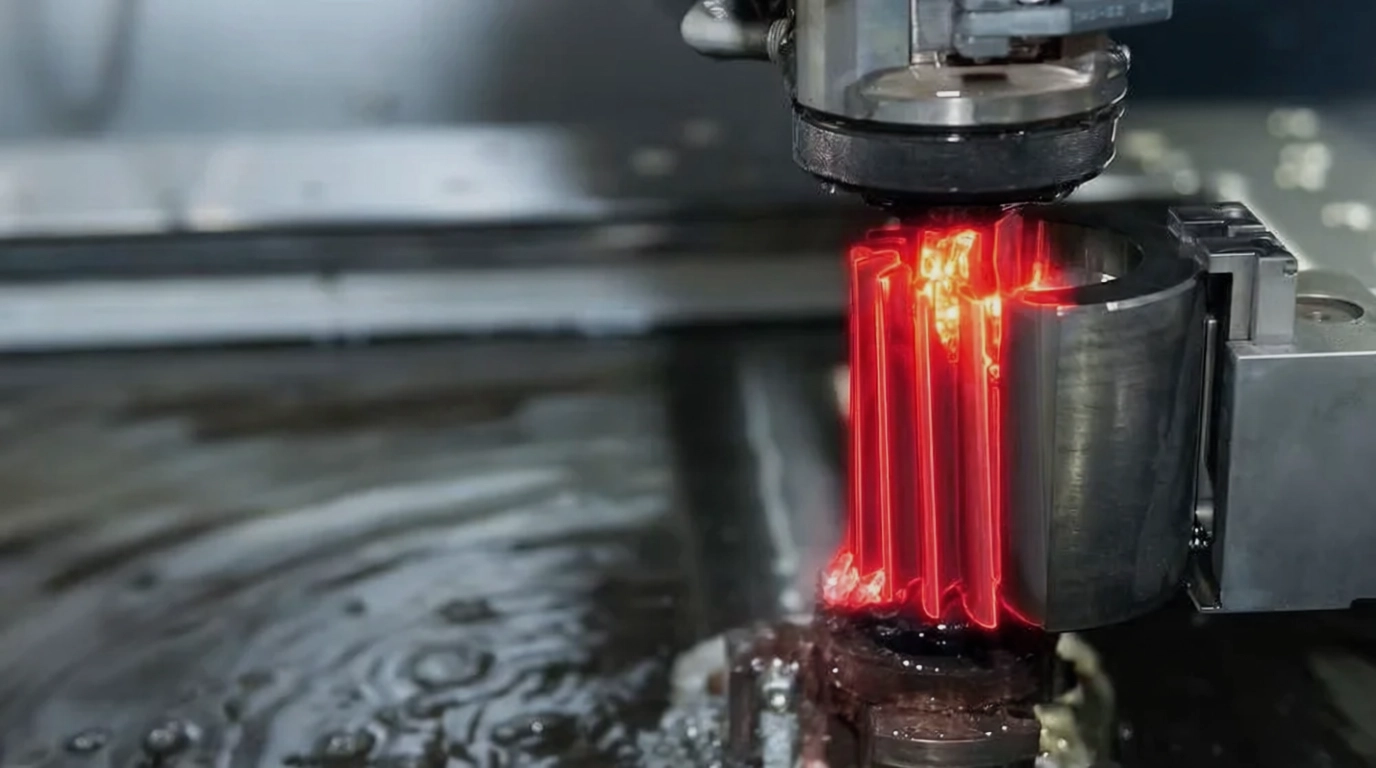

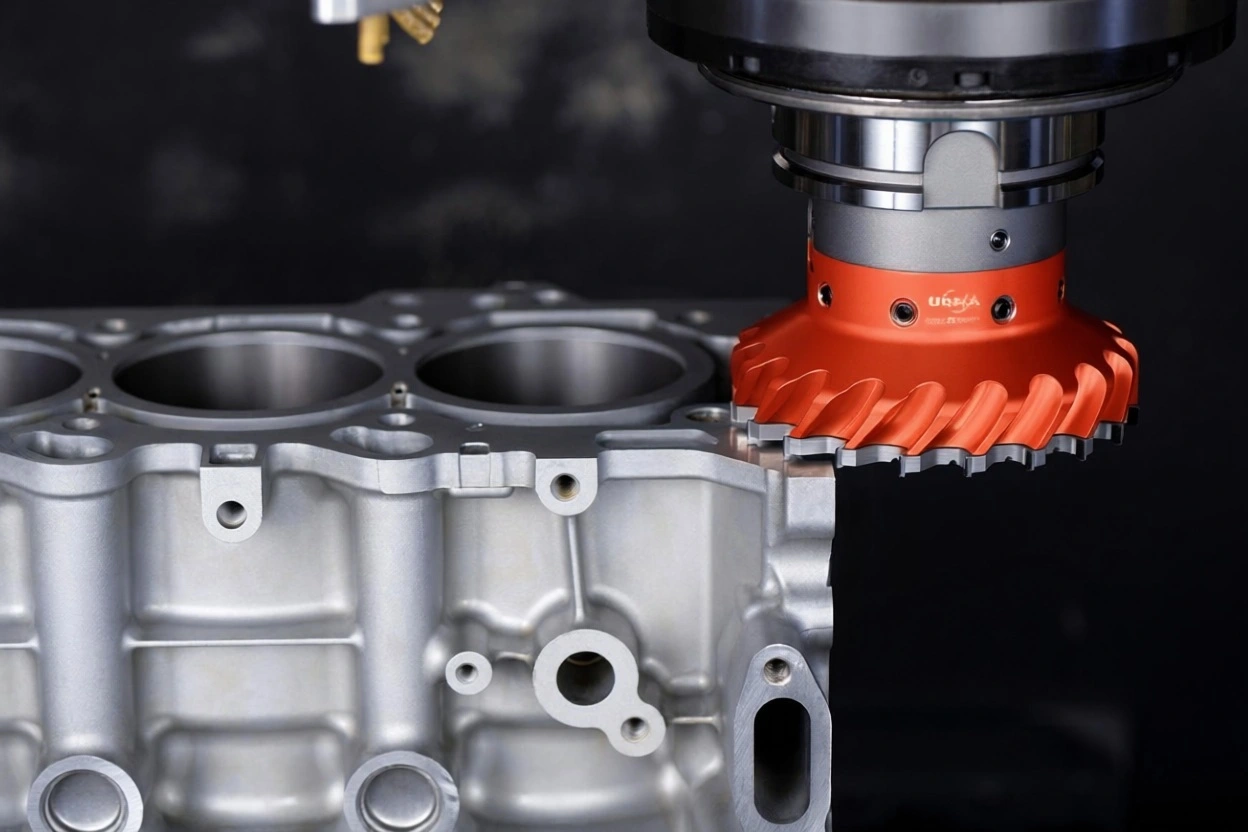

Metalworking machines include turning, milling, drilling, EDM, laser, and multi-axis CNC machining centers for complete metal part processing. They are used in mechanical engineering, energy, aerospace, automotive, medical, and other industries for both batch and custom production of complex components.

Subcategories

Wire cut EDM HQ-500GS3

Manual lathe C6140ZK

Wire cut EDM HQ-400FU

Wire cut EDM HQ-400FL

Manual lathe CA6261C

Vertical drilling machine Z4116A

Knee-type horizontal milling machine X6132BH

Manual lathe CA6250C

Vertical drilling machine Z5150A

Vertical drilling machine B34H

Metalworking machines form the backbone of modern industrial manufacturing. From conventional engine lathes to advanced 5-axis CNC centers with automatic tool and pallet changers, KNAVI GROUP offers solutions tailored to specific production requirements. Our partnerships with top Asian manufacturers ensure a balance of precision, reliability, and value.

Our portfolio covers universal machines for maintenance shops and R&D labs, as well as specialized systems for high-volume production: Swiss-type lathes, spherical turning machines, screw shaft machining centers, wire-cut EDM, and fiber laser cutters. All equipment meets international safety and performance standards.

Automation-ready accessories—bar feeders, chip conveyors, central coolant systems, and robotic loaders—enable seamless integration into smart factories and Industry 4.0 environments, reducing labor costs and maximizing uptime.

KNAVI GROUP supplies directly from factories, with full English documentation, up to 2 years of warranty, operator training, and optional on-site commissioning worldwide.