Electrical discharge machines (EDM)

EDM machines include wire-cut (WEDM), sinker, and copy EDM models with CNC for non-contact machining of conductive materials. They are used in mold & die making, aerospace, medical device manufacturing, and precision engineering to produce complex shapes from hardened steel, titanium, and exotic alloys.

Wire cut EDM HQ-500GS3

Wire cut EDM HQ-400FU

Wire cut EDM HQ-400FL

Wire cut EDM Wi-530S

Wire cut EDM Wi-L400S

CNC Die-sink EDM machine HQ-U60

ZNC Die-sink EDM machine HQ-540K

Wire cut EDM ALN600Gs

CNC EDM Wire Cut DK7750

Wire cut EDM Wi-60E

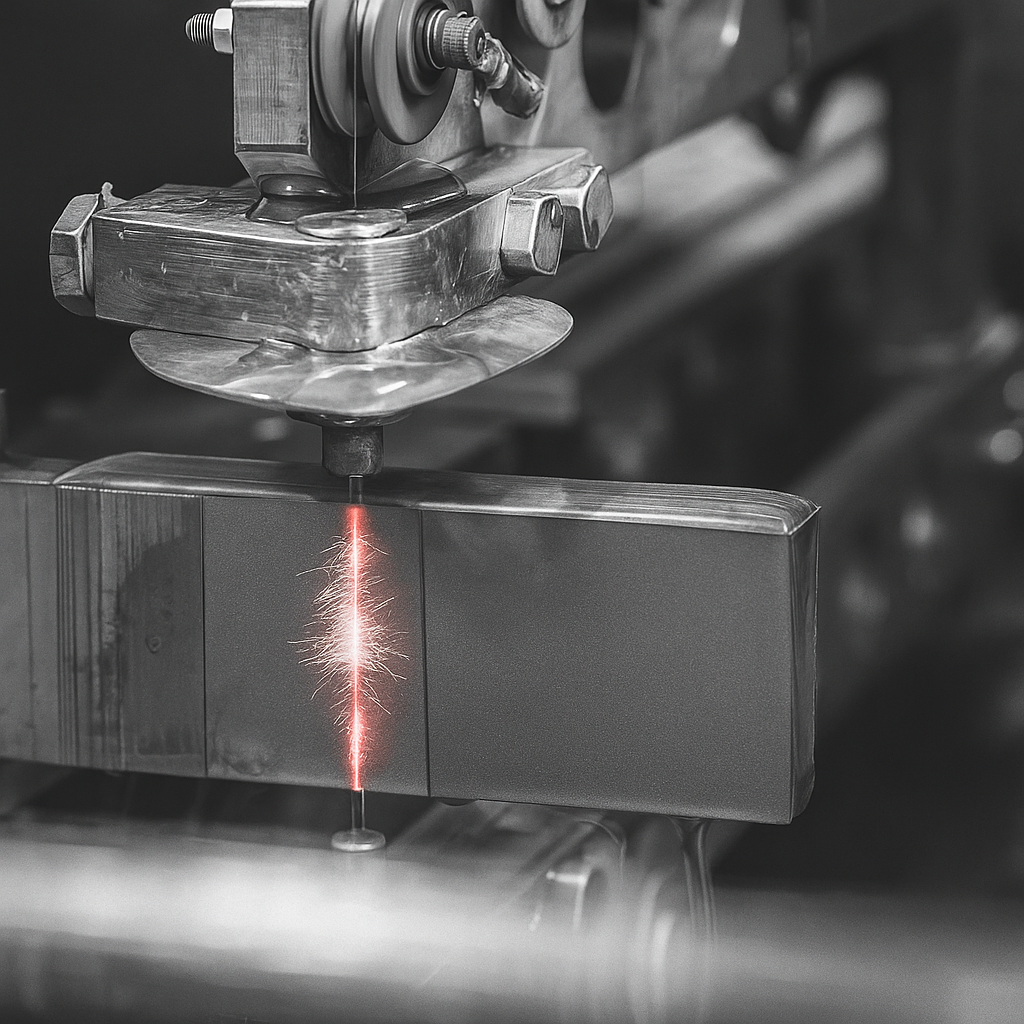

EDM (electrical discharge machining, also known as spark eroding or wire erosion) is a machining process that uses the electrical discharges to alter the shape of a workpiece - an electrical current passes between an electrode and a workpiece which are separated by a dielectric liquid and as a result spark erodes the workpiece to form a desired final shape.

Types of EDM machines:

- Wire-cut EDM (WEDM);

- Die-sink EDM (Ram-type EDM);

- Hole drilling EDM;

Combined with computer numeric controls (CNC), EDM machines become an accurate and reliable machining method that is now standard among more conventional cutting methods. It is particularly popular for small-volume productions such as prototypes. Various processes are possible with electrical discharge machining, including turning, milling, grinding and small hole drilling. Besides die and mould-making, EDM is typically applied in the automotive and aerospace industry, for example, in the production of aircraft engines.

Advantages:

- Machining the hight hardness workpieces made from titanium or tungsten carbide;

- Machining the shapes and depths what are impossible to process with a cutting tool;

- Excellent surface finish;

- High precision machining method

However, EDM machining is the rather slow method compared to traditional machining, therefore high-volume tasks are not suited for this method. At the same time, the spark eroding process requires high power consumption. If need to rough cut a lot of parts quickly, electrical discharge machining probably isn’t the right processing machine.

Reliable and durability EDM machines from Asia by Knavi Group LLC.

Knavi Group LLC offers a large variety of reliable EDM machines for any task by the largest manufacturers from China, Taiwan (R.O.C), Korea and Japan. A wide range of high quality machine tools with a long warranty and lowest prices. Assistance in the selection of a needed machine and equipment, installation supervision and commissioning, training, warranty and post-warranty maintenance, door-delivery to any region of the country, supply of spare parts and tools.