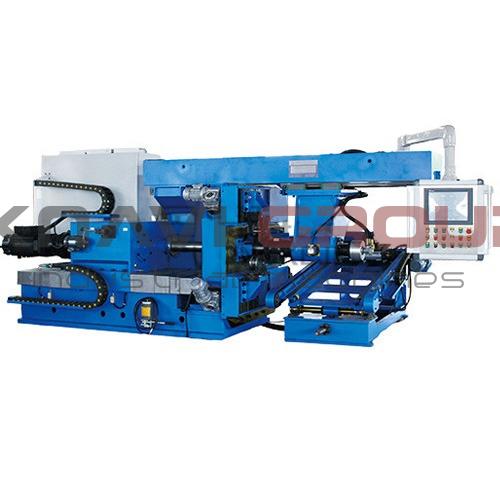

CNC hot-coiling spring machine HCM-65K

Price & Terms

Specifications

Indication and control

Processing parameters

Engines and power supply

Other

Overall dimensions and weight

Equipment

Description

HCM-65K CNC Hot Spring Coiling Machine

The HCM-35K CNC Hot Spring Coiling Machine is equipment for high-precision, automated, large-batch spring production. A multi-axis CNC controller manages the number of coils, pitch, and wire feed. All parameters are set via a touch screen panel.

Key Features:

Automation: Automatic clamping and spring connecting, mandrel cooling, adjustable feed angle.

Precision Feeding: Servo drive provides precise two-plane positioning of the feed rollers with angle adjustment.

Optimized Cooling: Combined water and air cooling system for the mandrel.

Intelligent Control: Motion controller coordinates all units; touch screen for parameter setup and storage.

Compact Connector: Reliable automatic spring connecting device with minimal space requirement.

Application: The ideal solution for the mass production of high-precision springs in the automotive industry, heavy machinery manufacturing, industrial equipment production, and other sectors where consistent quality and process automation are critical.

Products in This Series

Compare Series Products

CNC hot-coiling spring machine HCM-25

CNC hot-coiling spring machine HCM-35K

CNC hot-coiling spring machine HCM-50

CNC hot-coiling spring machine HCM-50K

CNC hot-coiling spring machine HCM-65