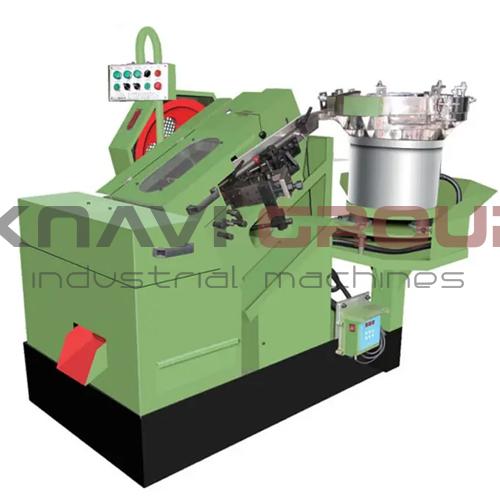

Threading rolling machine R10-100Z

Price & Terms

Specifications

Basic feauturies

Overall dimensions and weight

Equipment

Description

Key Advantages of the R10-100Z Thread Rolling Machine

• High Productivity — Delivers an output of 70–90 parts per minute, making the machine an efficient solution for mass production of fasteners.

• Processing Versatility — Handles workpieces with diameters up to 12 mm and can roll threads up to 100 mm in length, suitable for manufacturing bolts, studs, self-tapping screws, and other types of fasteners.

• Reliable Die System — Equipped with two working dies (a movable die measuring 170×30×100 mm and a stationary die measuring 150×30×100 mm), ensuring consistent rolling quality and extended tool life.

• Cold Forming Technology — Forms threads through plastic deformation without chip removal, enhancing the strength of the threaded joint by densifying the metal structure and preserving the material's fiber integrity.

• Ease of Operation — The automated work cycle minimizes operator involvement, while the thoughtfully designed construction simplifies maintenance and die replacement.

Products in This Series

Compare Series Products

Threading rolling machine R10-100Z

Threading rolling machine R10-300Z

Threading rolling machine R12-120Z

Threading rolling machine R16-200Z

Threading rolling machine R3-20Z

Threading rolling machine R4-25Z

Threading rolling machine R4-40Z

Threading rolling machine R5-50Z

Threading rolling machine R5-65Z

Threading rolling machine R6-120Z

Threading rolling machine R6-80Z

Threading rolling machine R8-130Z

Threading rolling machine R8-300Z