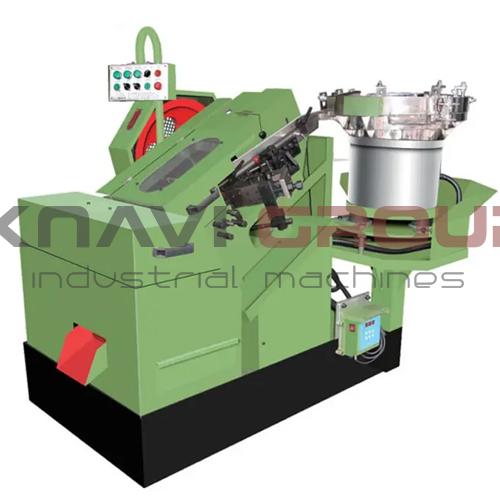

Threading rolling machine R4-25Z

Price & Terms

Specifications

Basic feauturies

Overall dimensions and weight

Equipment

Description

Key Advantages of the R4-25Z Thread Rolling Machine

• Specialization in Small Fasteners — Designed for rolling threads on workpieces with a diameter of 4 mm and a length of up to 25 mm, making the machine an optimal solution for producing screws, self-tapping screws, rivets, and other small fastening components.

• High Productivity — Delivers an output of 230 finished parts per minute, enabling efficient serial production of small fasteners while maintaining a compact equipment footprint.

• Cold Forming Technology — Forms threads through plastic deformation without chip removal, enhancing joint strength, improving the fatigue resistance of the component, and eliminating production waste.

• Precision Die System — Equipped with a set of high-precision miniature thread rolling dies (movable and stationary) that ensure consistent thread profile quality even during prolonged high-speed operation.

• Quick Changeover — A fast-change die clamping system and intuitive adjustments allow the operator to rapidly reconfigure the machine for a new thread size.

Products in This Series

Compare Series Products

Threading rolling machine R10-100Z

Threading rolling machine R10-300Z

Threading rolling machine R12-120Z

Threading rolling machine R16-200Z

Threading rolling machine R3-20Z

Threading rolling machine R4-25Z

Threading rolling machine R4-40Z

Threading rolling machine R5-50Z

Threading rolling machine R5-65Z

Threading rolling machine R6-120Z

Threading rolling machine R6-80Z

Threading rolling machine R8-130Z

Threading rolling machine R8-300Z