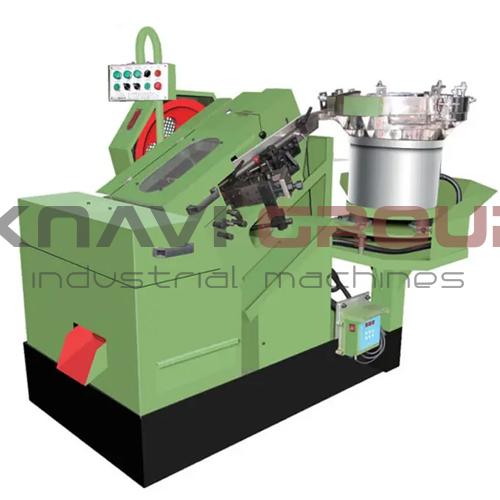

Threading rolling machine R10-300Z

Price & Terms

Specifications

Basic feauturies

Overall dimensions and weight

Equipment

Description

Key Advantages of the R10-300Z Thread Rolling Machine

• Capability for Long Workpieces — Designed for rolling threads on workpieces with a maximum length of up to 300 mm and a diameter of up to 10 mm, enabling the production of extended fastening elements such as studs, anchors, threaded rods, and other components with long threaded sections.

• Consistent Productivity — Delivers an output of 40–60 finished parts per minute, combining high processing speed with reliable quality even when manufacturing long components.

• Cold Forming Technology — Forms threads through plastic deformation without chip removal, enhancing the strength of the threaded joint by densifying the metal structure and preserving the integrity of the material's grain fibers.

• Robust Tooling System — Utilizes a set of precision thread rolling dies (movable and stationary) that ensure stable thread profile quality throughout the tool's service life.

• Application Versatility — Suitable for producing various types of external threads (metric, inch) on steel workpieces, including those made from alloyed and low-alloy steels.

Products in This Series

Compare Series Products

Threading rolling machine R10-100Z

Threading rolling machine R10-300Z

Threading rolling machine R12-120Z

Threading rolling machine R16-200Z

Threading rolling machine R3-20Z

Threading rolling machine R4-25Z

Threading rolling machine R4-40Z

Threading rolling machine R5-50Z

Threading rolling machine R5-65Z

Threading rolling machine R6-120Z

Threading rolling machine R6-80Z

Threading rolling machine R8-130Z

Threading rolling machine R8-300Z