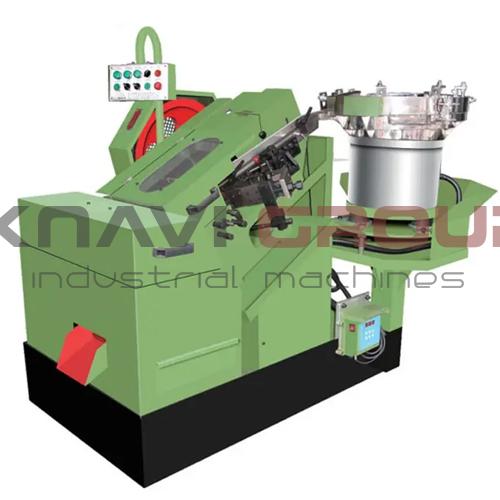

Threading rolling machine R8-300Z

Price & Terms

Specifications

Basic feauturies

Overall dimensions and weight

Equipment

Description

Key Advantages of the R8-300Z Thread Rolling Machine

• Processing of Extra-Long Threaded Components — Designed for rolling threads on workpieces with a maximum length of up to 300 mm, enabling the production of extended studs, threaded rods, anchor systems, and specialized fastening elements for construction and industrial applications.

• Stable Operation with Long Workpieces — A reinforced machine structure and an optimized workpiece support system ensure minimal deflection when processing components up to 300 mm in length, guaranteeing uniform thread profile quality along the entire length without thread geometry distortion.

• Balanced Productivity — Delivers an output of 40–60 finished parts per minute depending on workpiece diameter and thread profile complexity, making the machine an efficient solution for long fastener production without compromising quality.

• Cold Forming Technology with Strengthening Effect — Forms threads through plastic deformation without chip removal, enhancing joint strength, improving resistance to fatigue and dynamic loads, and preserving the integrity of material protective coatings.

• Extended-Length Dies — Equipped with precision thread rolling dies of increased length (up to 300 mm working zone), manufactured from high-quality tool steel with a hardened working surface to ensure stable thread profile quality and extended tool life.

Products in This Series

Compare Series Products

Threading rolling machine R10-100Z

Threading rolling machine R10-300Z

Threading rolling machine R12-120Z

Threading rolling machine R16-200Z

Threading rolling machine R3-20Z

Threading rolling machine R4-25Z

Threading rolling machine R4-40Z

Threading rolling machine R5-50Z

Threading rolling machine R5-65Z

Threading rolling machine R6-120Z

Threading rolling machine R6-80Z

Threading rolling machine R8-130Z

Threading rolling machine R8-300Z