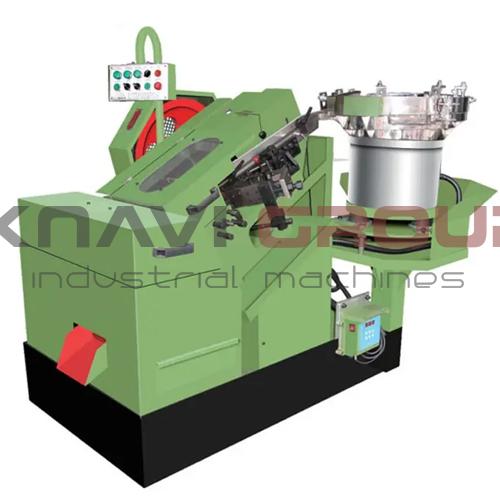

Threading rolling machine R6-120Z

Price & Terms

Specifications

Basic feauturies

Overall dimensions and weight

Equipment

Description

Key Advantages of the R6-120Z Thread Rolling Machine

• Versatility for Medium-Diameter Workpieces with Extended Threads — Designed for rolling threads on workpieces with a diameter of 8 mm and a length of up to 120 mm, enabling the production of studs, threaded rods, anchor bolts, and other fastening elements with extended threaded sections.

• Balanced Productivity — Delivers an output of 80 finished parts per minute, optimally combining processing speed with consistent quality when manufacturing longer components.

• Cold Forming Technology — Forms threads through plastic deformation without chip removal, enhancing the strength of the threaded joint, improving fatigue resistance, and preserving the integrity of protective coatings on the workpiece surface.

• Specialized Extended-Length Dies — Equipped with precision thread rolling dies (movable and stationary) with a working length of up to 120 mm, ensuring uniform thread profile formation along the entire length without distortion of thread geometry.

• Rapid Changeover and Ease of Maintenance — A quick-change die clamping system, digital indication of key parameters, and convenient access to friction units enable fast reconfiguration for new thread sizes and straightforward routine maintenance.

Products in This Series

Compare Series Products

Threading rolling machine R10-100Z

Threading rolling machine R10-300Z

Threading rolling machine R12-120Z

Threading rolling machine R16-200Z

Threading rolling machine R3-20Z

Threading rolling machine R4-25Z

Threading rolling machine R4-40Z

Threading rolling machine R5-50Z

Threading rolling machine R5-65Z

Threading rolling machine R6-120Z

Threading rolling machine R6-80Z

Threading rolling machine R8-130Z

Threading rolling machine R8-300Z