Bending and forming machinery

Bending and forming equipment includes CNC spring coiling machines, multi-formers, cold heading, thread rolling, and straightening-cutting systems for wire and rod processing from 0.1 to 25 mm in diameter. It is used to manufacture springs, fasteners, pins, electrodes, and precision components for automotive, medical, and electronics industries.

Subcategories

10-axis CNC spring former FP-S1008

Straightening and cutting machine GT-SF6

3-axis CNC spring forming machine YF-8335

2-axis CNC spring coiling machine YF-8212

CNC Spring forming machine HCT-35W

3-axis CNC spring forming machine CNC-635

Straightening and cutting machine QP-09

Spring forming machine HCT-1225WZ

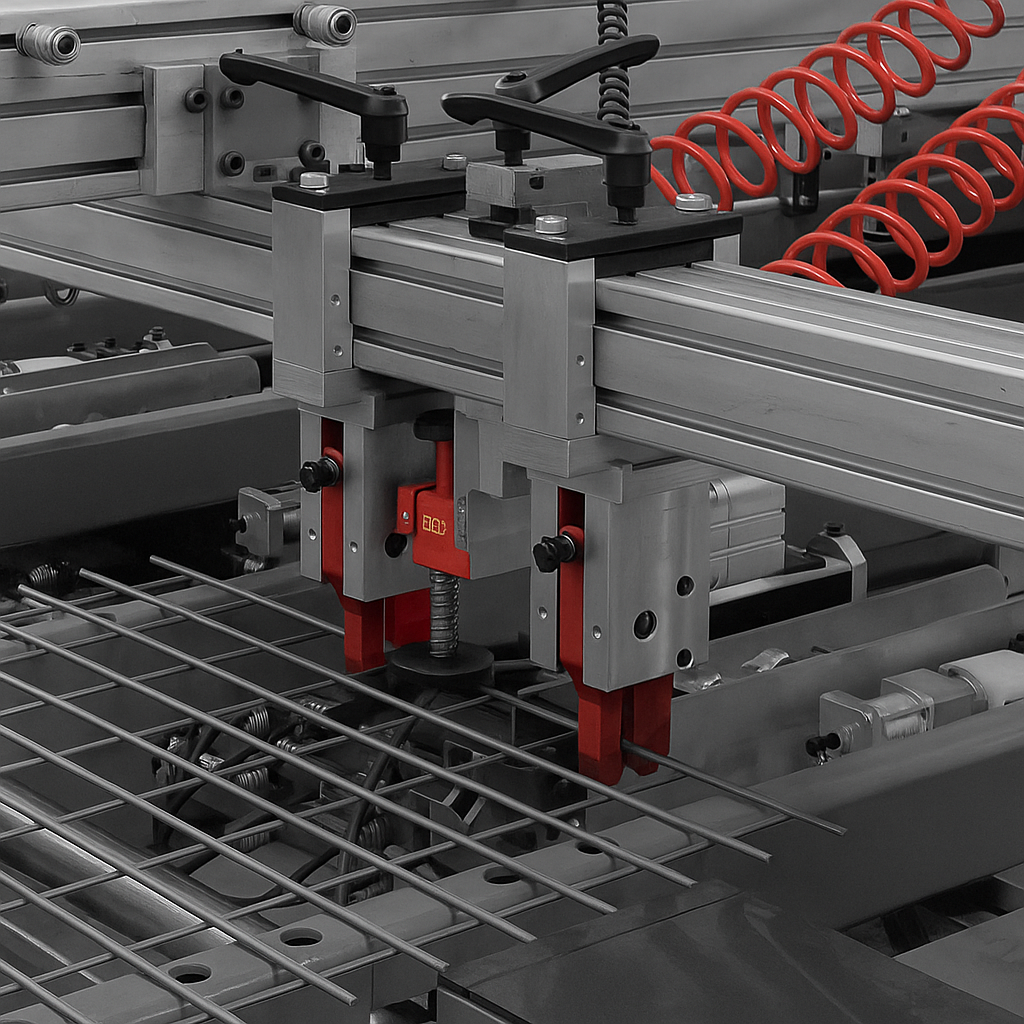

Crimping wire mesh weaving machine CRW612

4-axis CNC spring forming machine 40T-4A

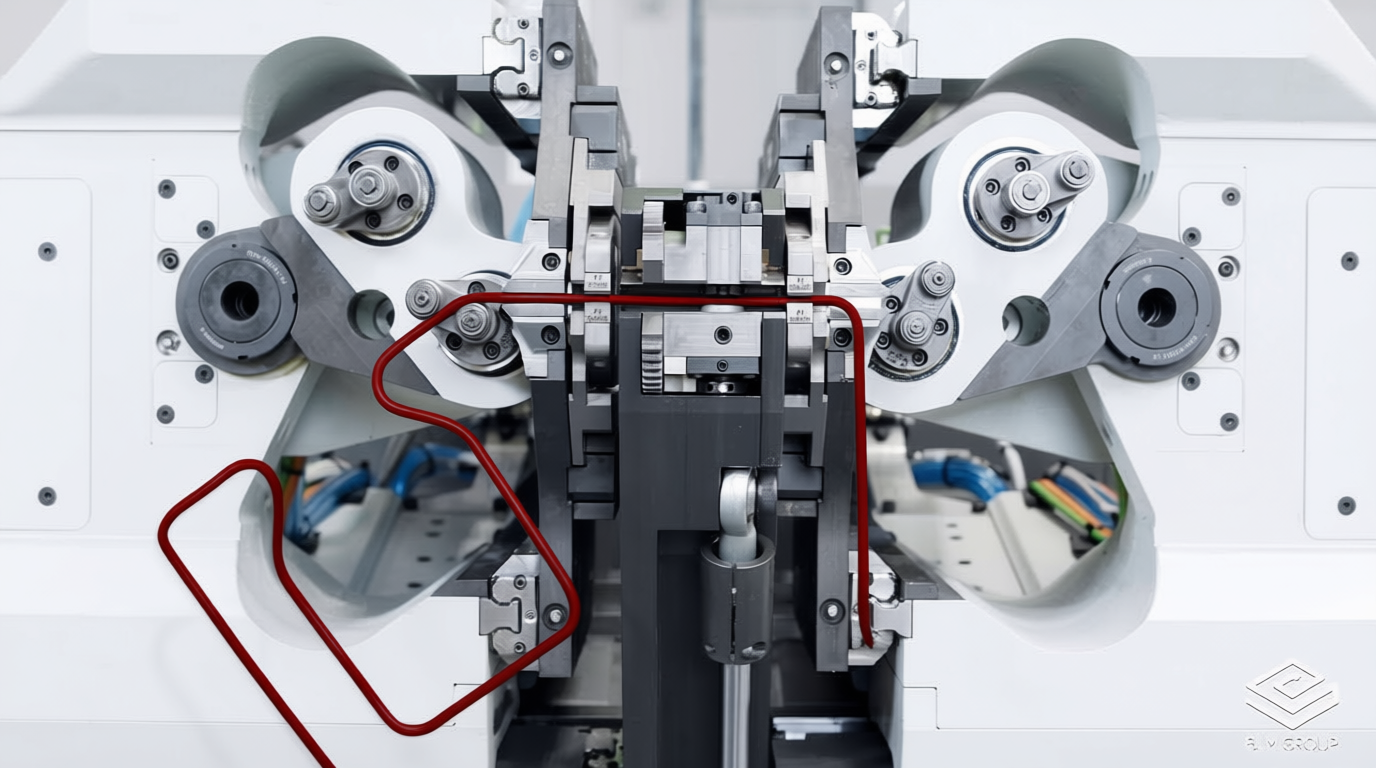

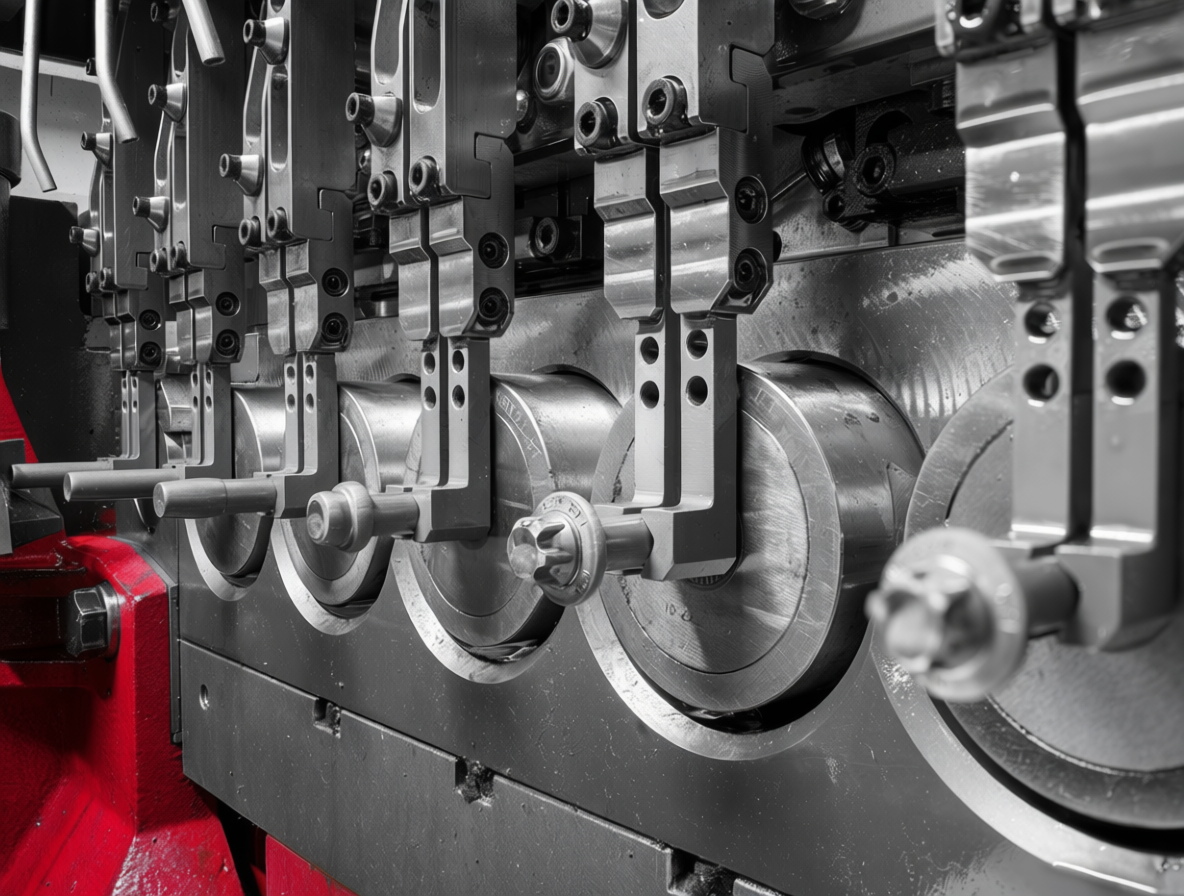

Modern bending and forming machines produce complex wire parts in a single cycle—from straightening and cutting to 3D coiling and profiling. CNC spring coilers with 2–7 axes manufacture compression, tension, and torsion springs, while multi-formers handle intricate geometries like double torsion and custom-shaped profiles.

Cold heading machines enable high-speed, high-strength production of bolts, screws, and rivets without heating the material—preserving grain structure and mechanical properties. Thread rolling machines form threads by cold forming, significantly improving fatigue resistance compared to cutting.

KNAVI GROUP supplies equipment from top Asian manufacturers including KDE, WNJ, ODMAY, JOTING, YUHAI, and YangLi. All machines meet international standards, come with full English documentation, and include up to 2 years of warranty.

Direct factory supply ensures competitive pricing. Every system includes operator training and optional on-site commissioning worldwide.